What are the different types of touchscreens and how are they used?

What are touchscreens?

The Purpose of Touchscreens

Touchscreens are input devices such as touchpads positioned over liquid crystal panels that allow user input and function display. And because touchscreens make it possible for someone to intuitively and directly input and control displayed prompts such as “push” or “slide,” they are exceptionally user-friendly.

Where are touchscreens used?

Touchscreens have become familiar to many of us. Smartphone and portable phone manufacturers use touchscreens for their display screens, and banks use touchscreens in their ATMs. But beyond that, more and more we are interacting with touchscreens in tablet computers, portable game consoles, car navigation systems, multimedia stations, arcade games, information boards, restaurant order systems and countless more places and industries. In just the last few years, they have become common in our daily lives.

The Different Types of Touchscreen Technologies

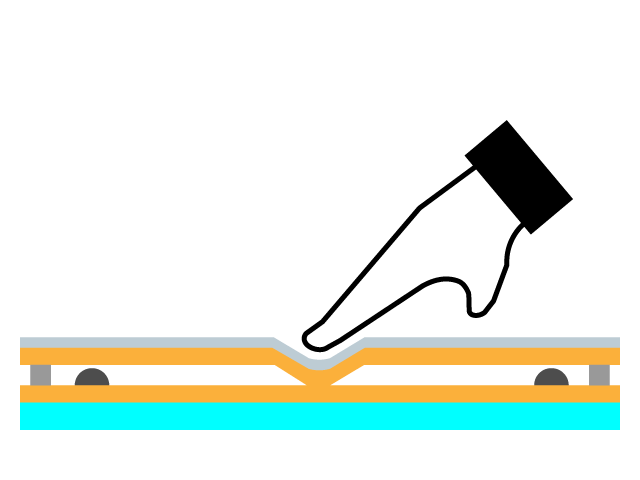

Resistive Touch Technology

Resistive touchscreens are composed of two electrically conductive layers of thin metal film separated by a tiny air gap. When pressure is applied to the surface of the touchscreen, the two sheets are pressed together, and a circuit is completed. The advantages of resistive touchscreens are that they are relatively cheap to produce and are cost-efficient to use. They also use uncomplicated algorithms. The disadvantages of resistive touchscreens are a lack of input precision when used with larger screens and a lack of overall screen clarity.

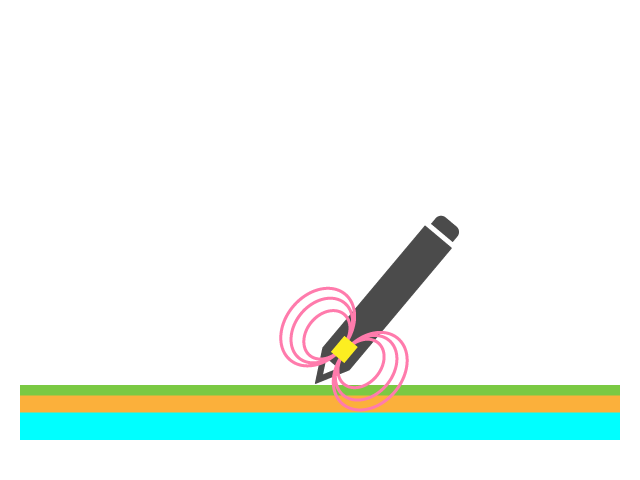

Electromagnetic Guidance Technology

An electromagnetic guidance touchscreen sends out an electrical charge that reacts with a stylus. The stylus then sends out a signal that allows the touchscreen to precisely identify its position. The placement of an electromagnetic induction sensor under a liquid crystal screen makes performing highly detailed operations possible, unlike a capacitive touchscreen. One disadvantage of electromagnetic guidance touchscreens is they require a designated stylus.

Optical Touchscreen Technology

Optical touchscreens use infrared emitters combined with infrared image sensors to continuously scan the touchscreen. When an object comes into contact with the touchscreen, it blocks some of the infrared light being received by the sensors. The location of the contact is then calculated by using information from both sensors and mathematical triangulation. Much like ultrasound surface wave acoustic touchscreens, optical touchscreens have high transmittance and because they use infrared sensors, can be operated by both conductive and non-conductive materials. Optical touchscreens support multi-touch events and gestures calculated by algorithms. The size of optical touchscreens is easy to scale, thereby making them well-suited for TV news and other television broadcasts.

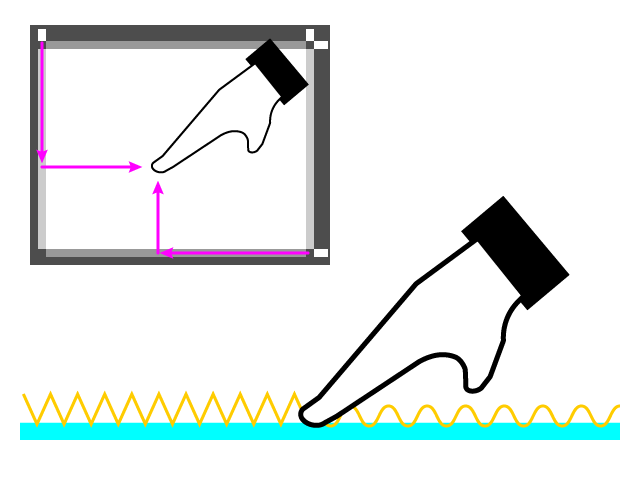

Surface Acoustic Wave Technology

Ultrasound surface wave acoustic touchscreens operate by tracking ultrasonic sound waves to identify the location of points on a screen. Surface wave acoustic touchscreens are made with a single pane of glass, a transmitter, and two piezoelectric receivers. The transmitter produces ultrasonic waves that move over the screen, reflect and then are read by the receiving piezoelectric receivers. When the surface of the glass is touched, some acoustic waves are absorbed, but some bounce back and are detected by the piezoelectric receivers. Because ultrasound surface wave acoustic touchscreens use glass, they have high transmittance and long operating lives. Ultrasound surface wave acoustic touchscreens are often used in the medical field, casinos, amusement facilities, public facilities, and financial institutions.

Capacitive Touch Technology

Capacitive touchscreens are coated with a transparent conductive film. When a fingertip comes into contact with a capacitative touchscreen, it can use the conductivity of the human body as a means for input. Electrostatic capacitive touchscreens are used in numerous smartphones such as Apple iPads and iPhones. Unlike resistive type touchscreens, electrostatic capacitive touchscreens are highly responsive yet cannot react to styluses or the touch of a fingernail. The disadvantages of capacitive touchscreens are they only react to a conductive material, and they may not work correctly if wet.

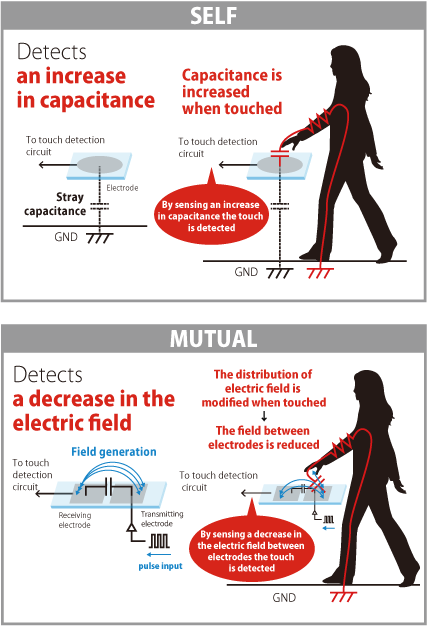

Self and Mutual Capacitive Touch Sensing Patterns

The mutual capacitive models can be made even more robust against water drops or even streams by appropriate fail-safe programming at the host controller.

Noritake’s Touchscreen Technology

Projected Capacitive Technology

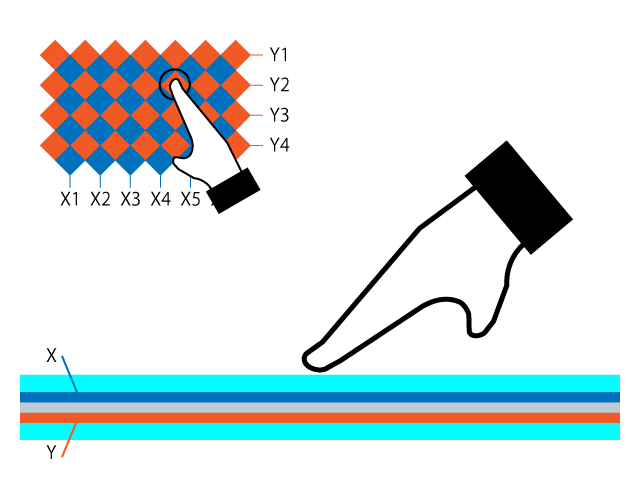

Noritake uses projected capacitive technology. There are two types of capacitive touchscreens; surface capacitive and projected capacitive.

A surface capacitive touchscreen uses a transparent layer of conductive film overlaid onto a glass sublayer. A protective layer is then applied to the conductive film. Voltage is applied to the electrodes on the four corners of the glass sublayer to generate a uniform electric field. When a conductor touches the screen, current flows from the electrodes to the conductor. The location of the conductor is then calculated based on the activity of the currents. Surface capacitive touchscreens are often used for large screen panels.

Projected capacitive touchscreens are extremely precise and quick to respond and are typically found on smaller devices such as iPhones, iPod touches, or iPads. Unlike the surface capacitive touchscreens, which use four electrodes and a transparent conductive film, the projected capacitive touchscreens use a vast amount of transparent electrodes arranged in a specific pattern and on two separate layers. When a conductor moves near the screen, the electrical field between the electrodes changes, and sensors can instantly identify the location on the screen. Projected capacitive touchscreens can accurately register multi-touch events.

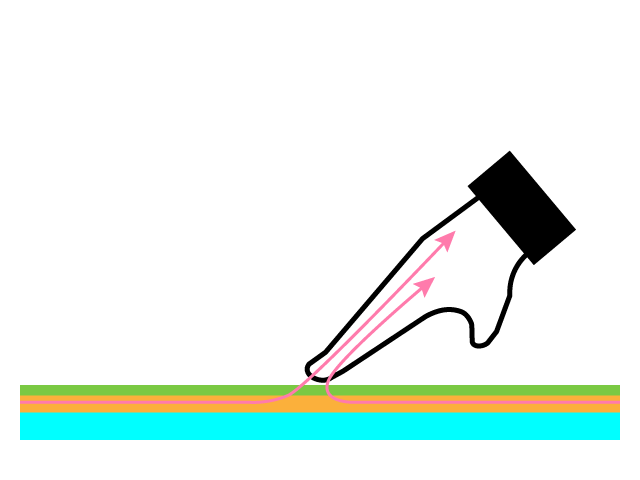

The Features of Noritake’s Touchscreens

Noritake’s touch panels are made with thin film technology.

Noritake’s touch panels have higher sensitivity than ordinate touch panels (like ITO) and offer reliable operation with thicker cover glass and compatibility with a variety of gloves.

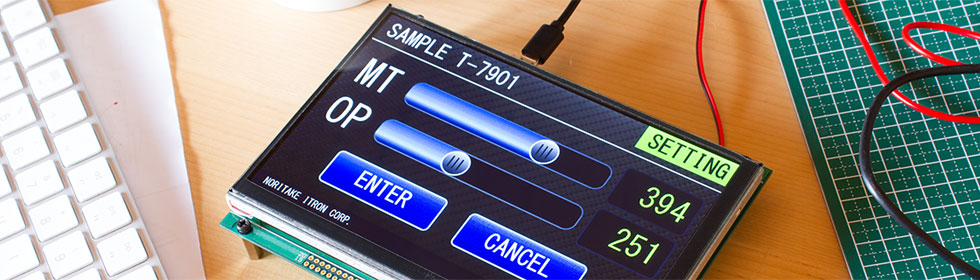

We provide

high performance

touch LCDs displays for

industrial, commercial and retail applications.

Who We Are

Noritake’s electronics division has been around since the creation of the Vacuum Fluorescent Display(VFD). We have grown to provide a wide array of products and services to ensure a smooth and efficient development cycle for your application. Our customer support staff will gladly provide you with technical support to assist with your needs.

We offer an expanding set of support tools for each of our product series, including code libraries and design programs. These tools work to accelerate the evaluation and integration procedures in order to have your prototype up and running as quickly as possible.

Noritake History

Noritake Itron Corp. (Ise Electronics Corp.) a subsidiary of Noritake Co., Ltd. Japan, invented the Vacuum Fluorescent Display in 1967. This unique display technology was introduced to the world by an article in Electronics Magazine issued May 29, 1967. The first developed single-digit display tube contributed to the evolution of electronic calculators in the 1970s. After the development of the flat glass structure VFD in 1974, its applications have been expanded to typewriters, home appliances, audio, video, automotive panels, industrial instruments, gaming machines, medical and communication equipment throughout its technological progression.

Noritake Itron, as a unique technology group, continues to challenge the human interface device industry with new products such as capacitive touch glass and the EMI shield window using high-density thin film patterning and vacuum process.

Noritake Services

Noritake serves you in lab settings, prototype production and assemblies, by utilizing Noritake core technologies acquired by developing and manufacturing Vacuum Fluorescent Displays since 1967. Please contact us if any of our technologies interest you or request free trial samples.

Noritake Products

Noritake offers a variety of TFT modules that can meet your application needs.

GT Product Features

- FLETAS® Metalized Projective Capacitive Touch

- Custom Touch Adjustment (Data Package) Available

- Free Design Resources (Including Evaluation Tools)

- High Brightness TFT & Industrial Grade PCB Design

- Long-Term Support Policy

Noritake Solutions

We have seen many problems and requests for systems in the market. Customers often need a product that can operate within a wide temperature range, offers an industrially rugged interface, and withstands outside interferences, including liquids. Our products are the solution to these issues.

Problem-solving, integration, and management are a breeze with our help. We can direct you to the display that meets your requirements, help you understand our product, and provide a stable product supply.