Series: GT-VP Touch Comparison

GT-1P Touch Comparison | Air-Gap

Table of Contents

Last update: August 17, 2018

https://www.youtube.com/watch?v=wmH0iST4ag4

This webpage is intended as a text supplement for the video above. This page will provide all of the necessary information (web links, images, etc.) that the video does if you are unable to view the video.

Overview

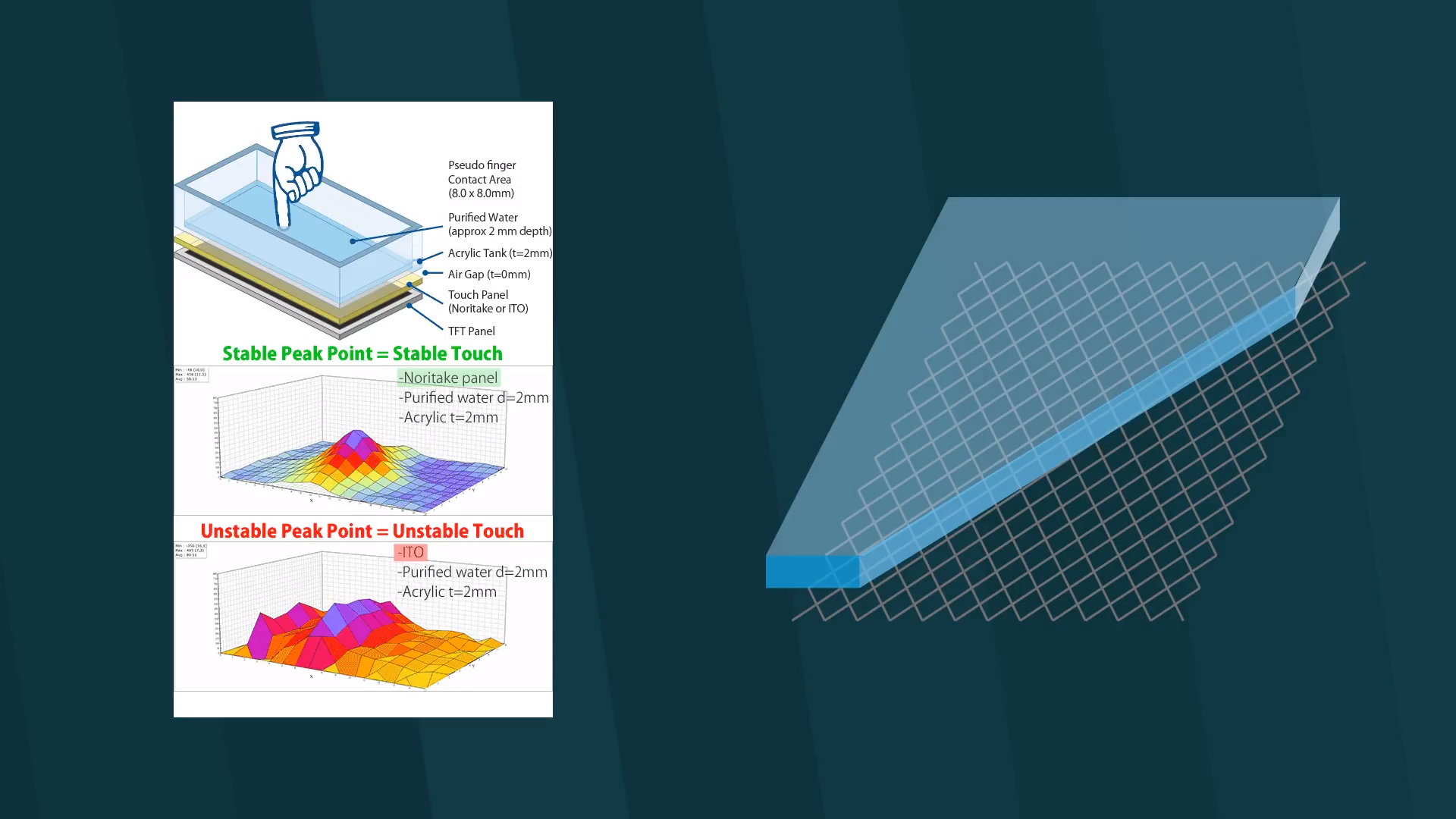

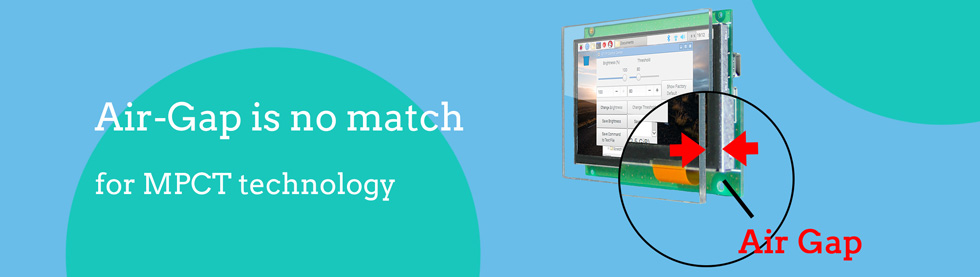

We are going to compare the performance difference between ITO and aluminum touch panels focusing on having an air gap between the touch panel and overlay.

Introducing an air gap into a design is often taken into consideration for keeping the display and protective overlay independent from each other as this will reduce manufacturing and maintenance costs of the end product.

To assess the performance difference, we are going to test the GT-1P module and a competitors’ module with the same display and touch interfaces.

Device Differences

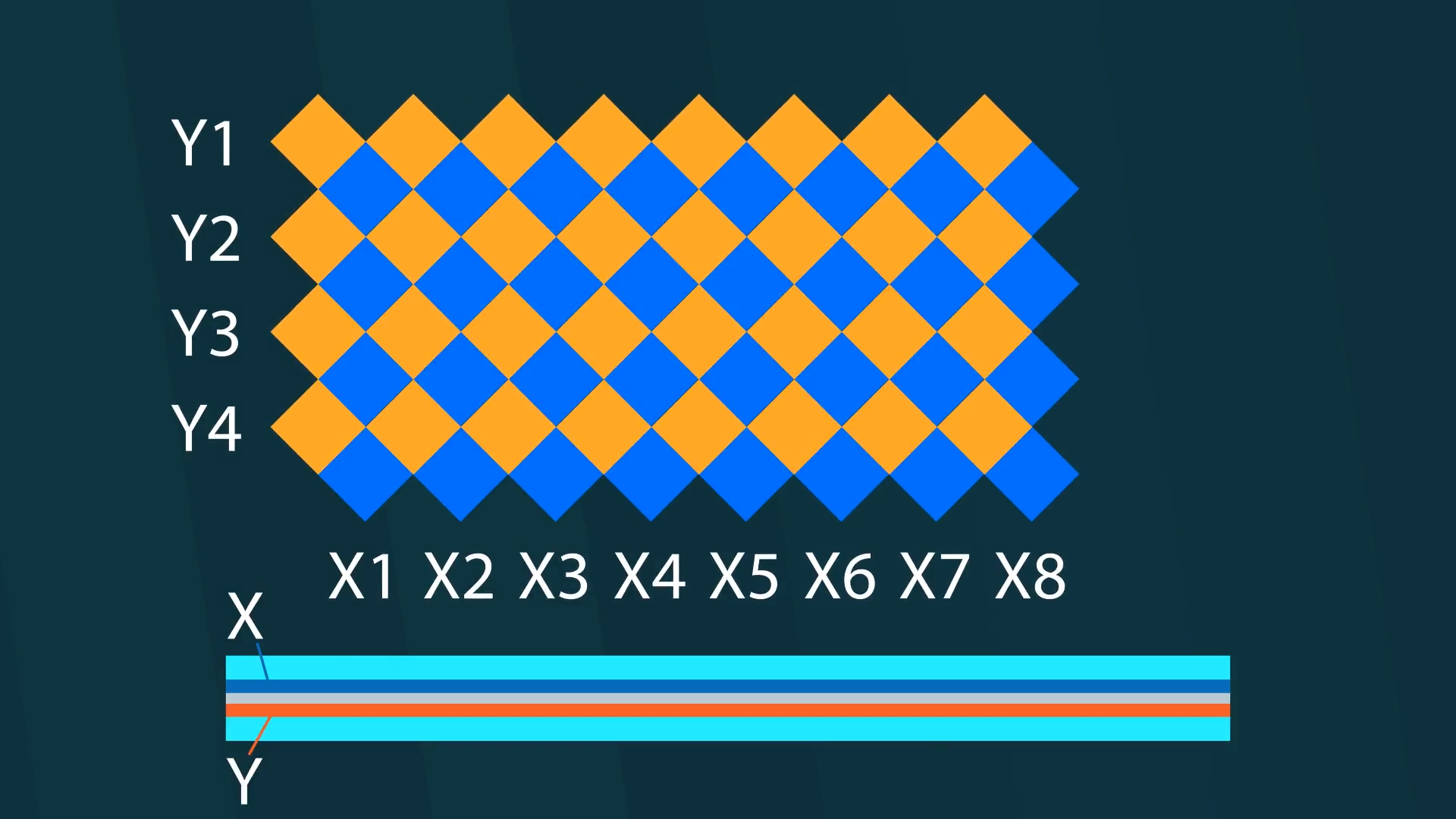

Both of these modules use a PCAP touch panel. This technology uses a vast amount of transparent electrodes arranged in a specific pattern on two separate layers.

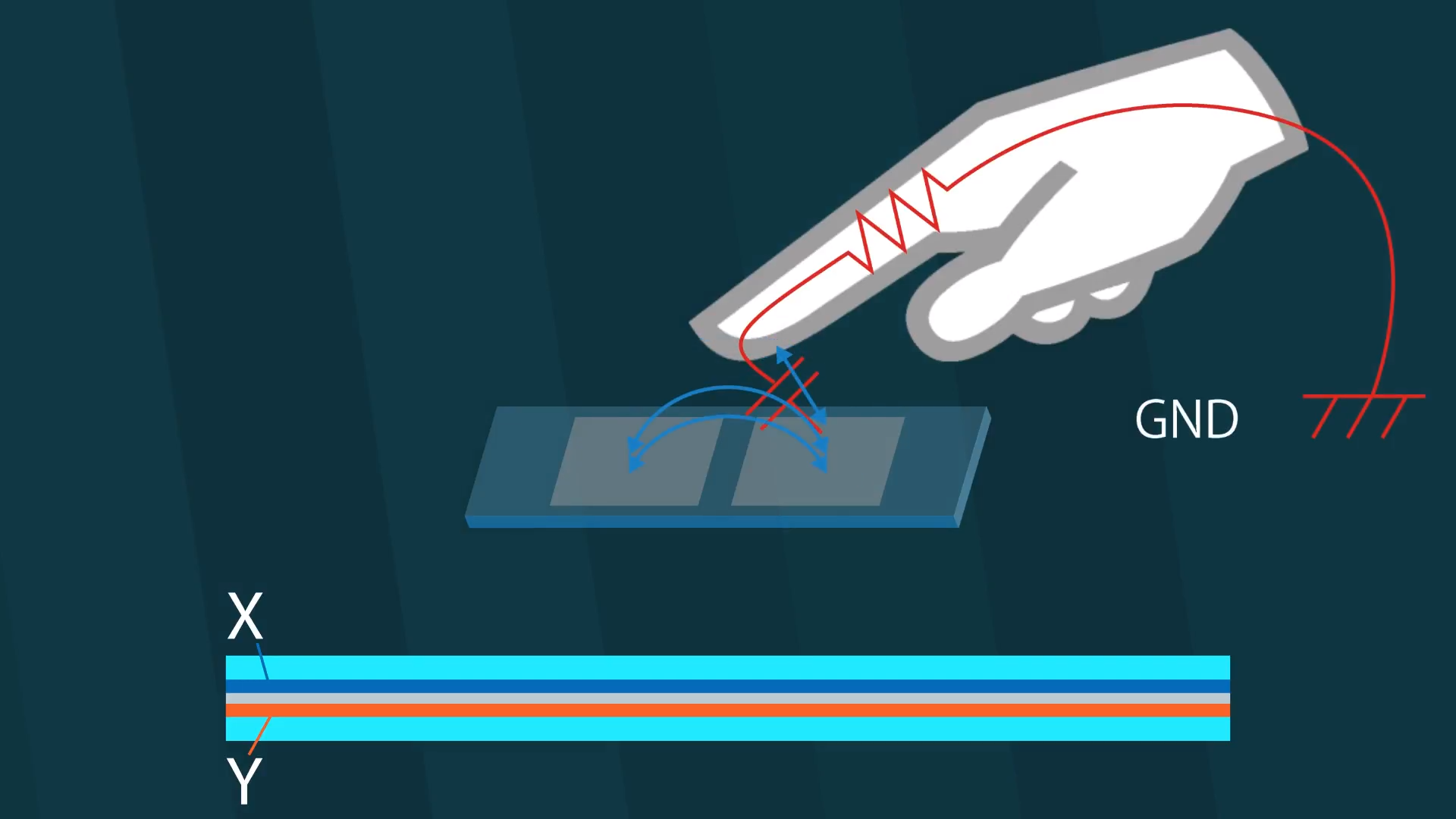

In order to detect touch, the finger or conductor only needs to move near the screen into the electrical field present between the electrodes. If this field is reduced, a touch will be registered.

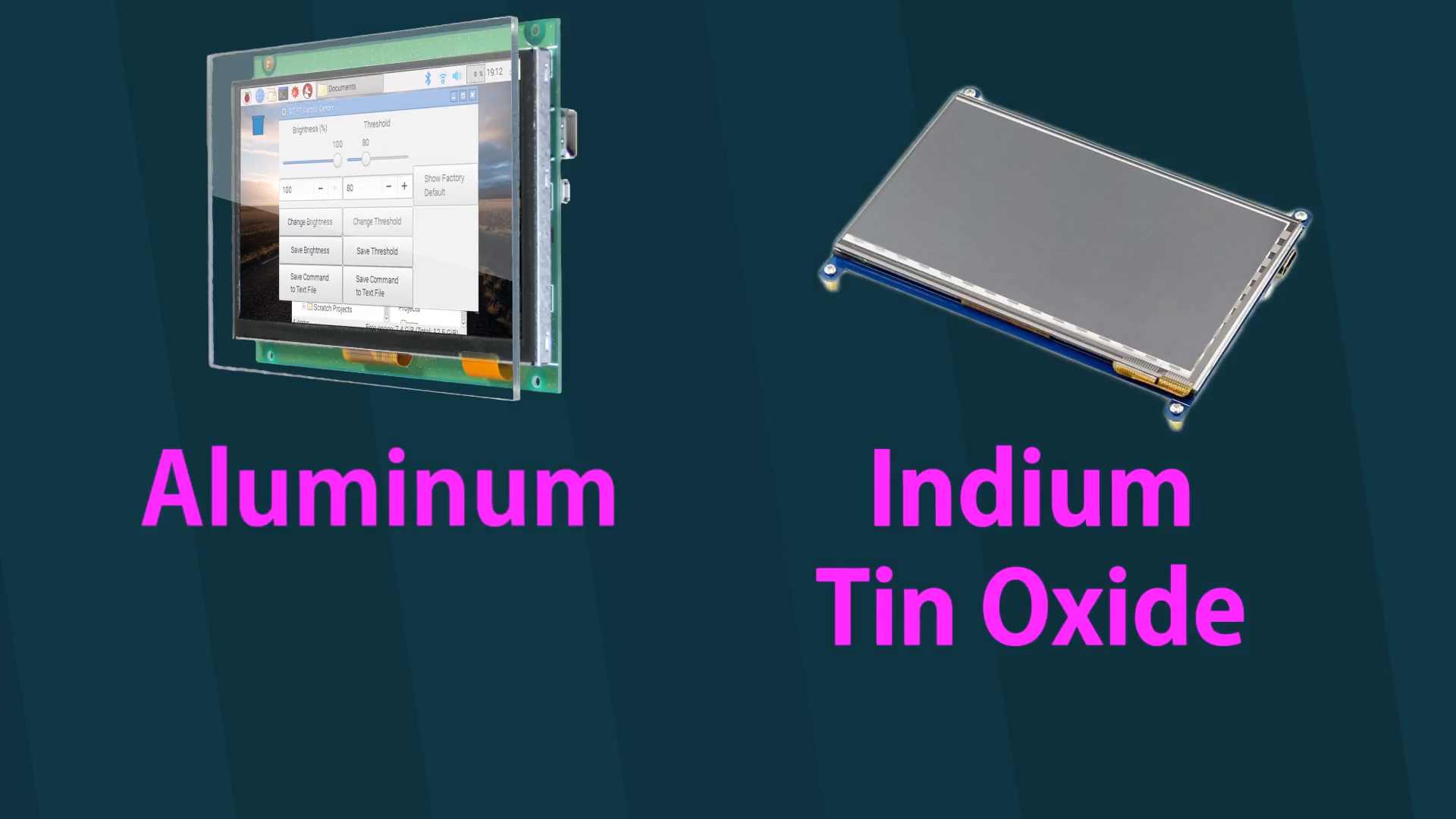

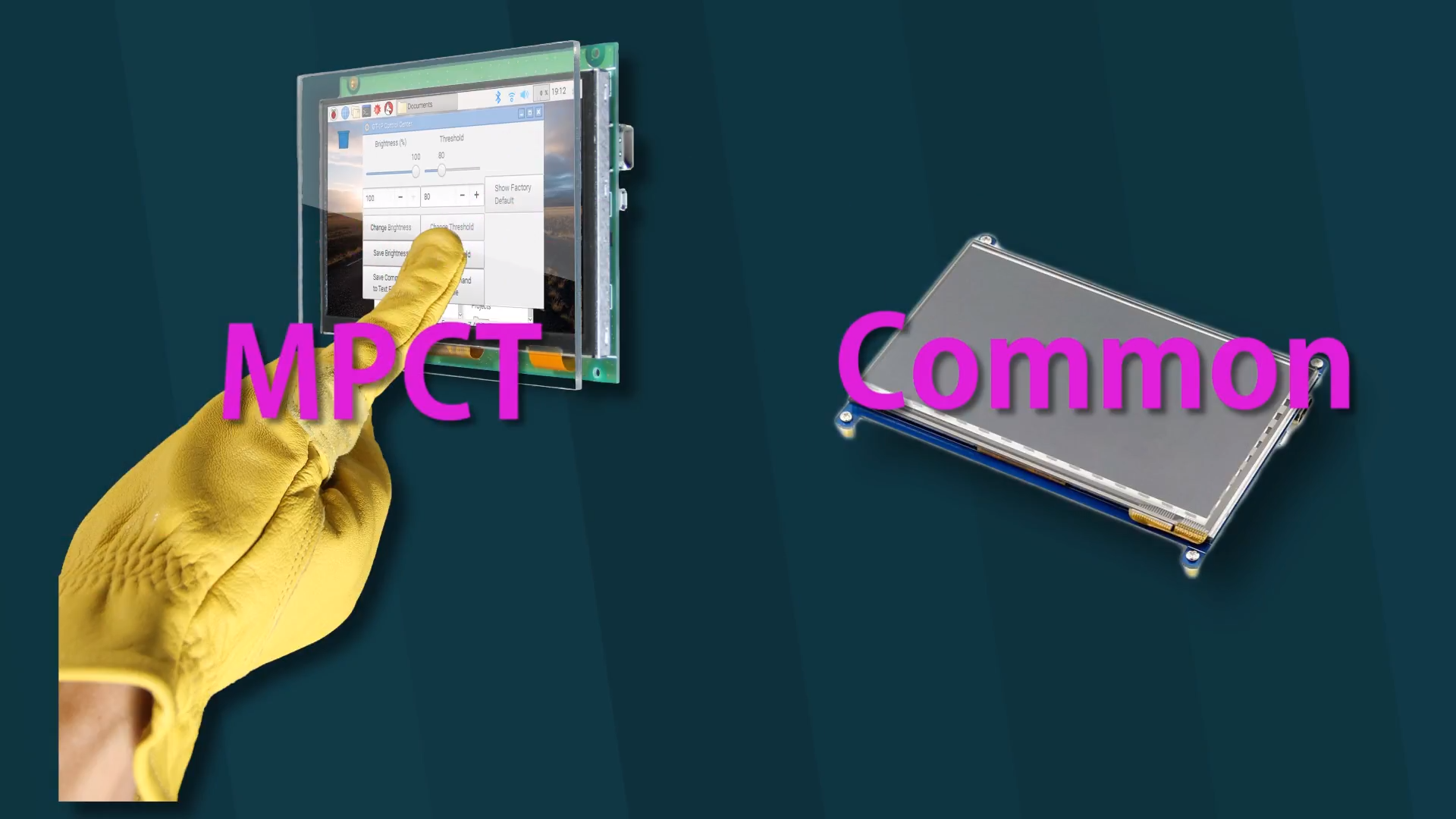

The big difference between these modules is the material each product uses. The competitor uses indium tin oxide, and our MPCT touch panel uses aluminum. MPCT stands for Metalliztd Projective Capacitive Touch and implements a thin pitch aluminum

mesh for the touch electrodes.

The aluminum helps our touch panel yield high signal-to-noise ratio which grants high sensitivity in operation with an air gap and gloves. This high signal-to-noise ratio is a constant factor within all of our MPCT touch panels.

For the rest of this demonstration, the product with ITO touch will be referred to as a common touch screen while the product with aluminum touch will be referred to as an MPCT touch screen.

Now that you know the differences between these two technologies let’s test them out.

Air-Gap Touch Test

Each test will use the same overlay material and thickness as the control, with a changing air gap as the variable. We will perform a zero, one-millimeter and three-millimeter air gap test along with a bonus test using a 3-millimeter air gap

and leather gloves.

Air-Gap Touch Test

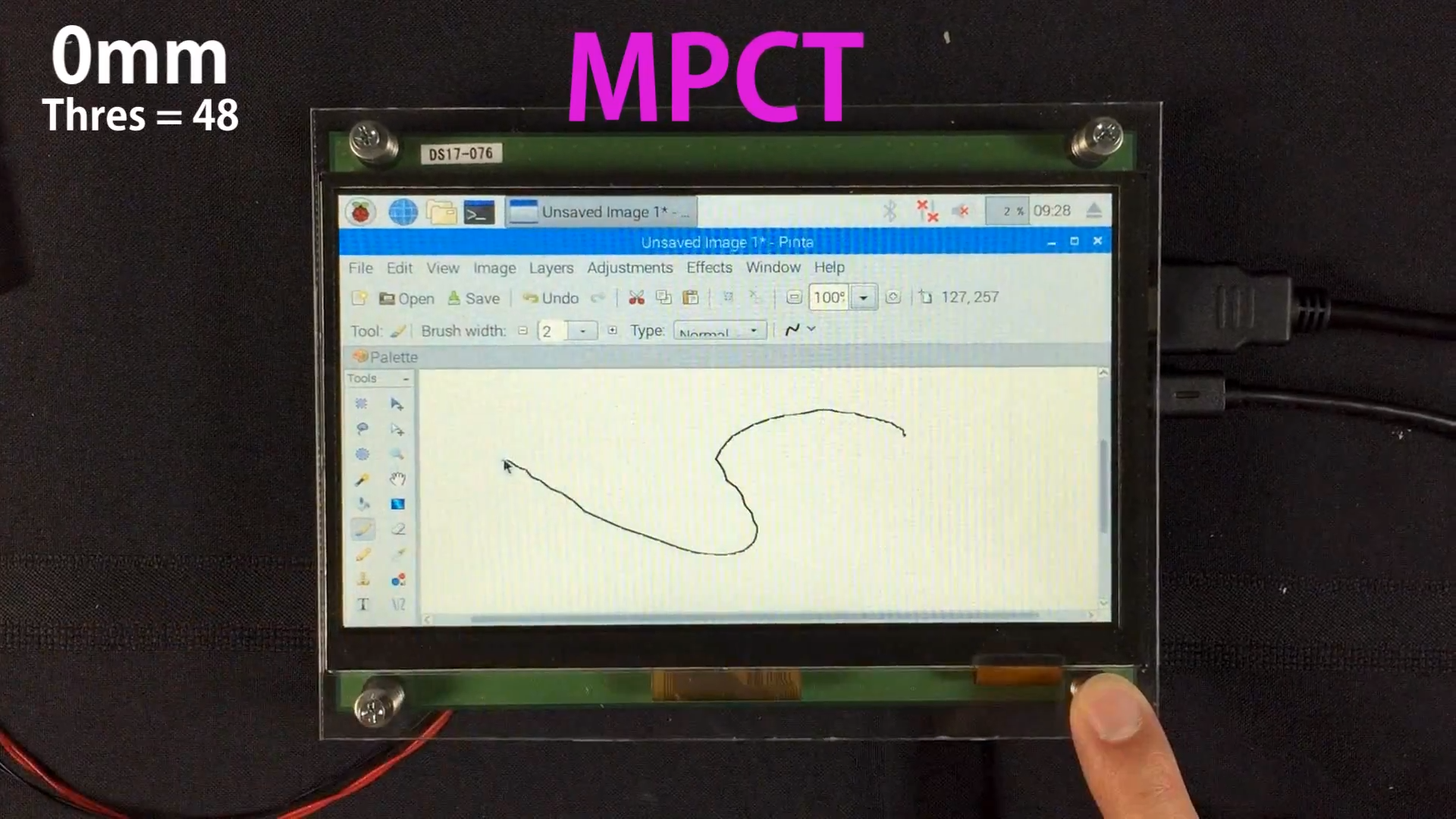

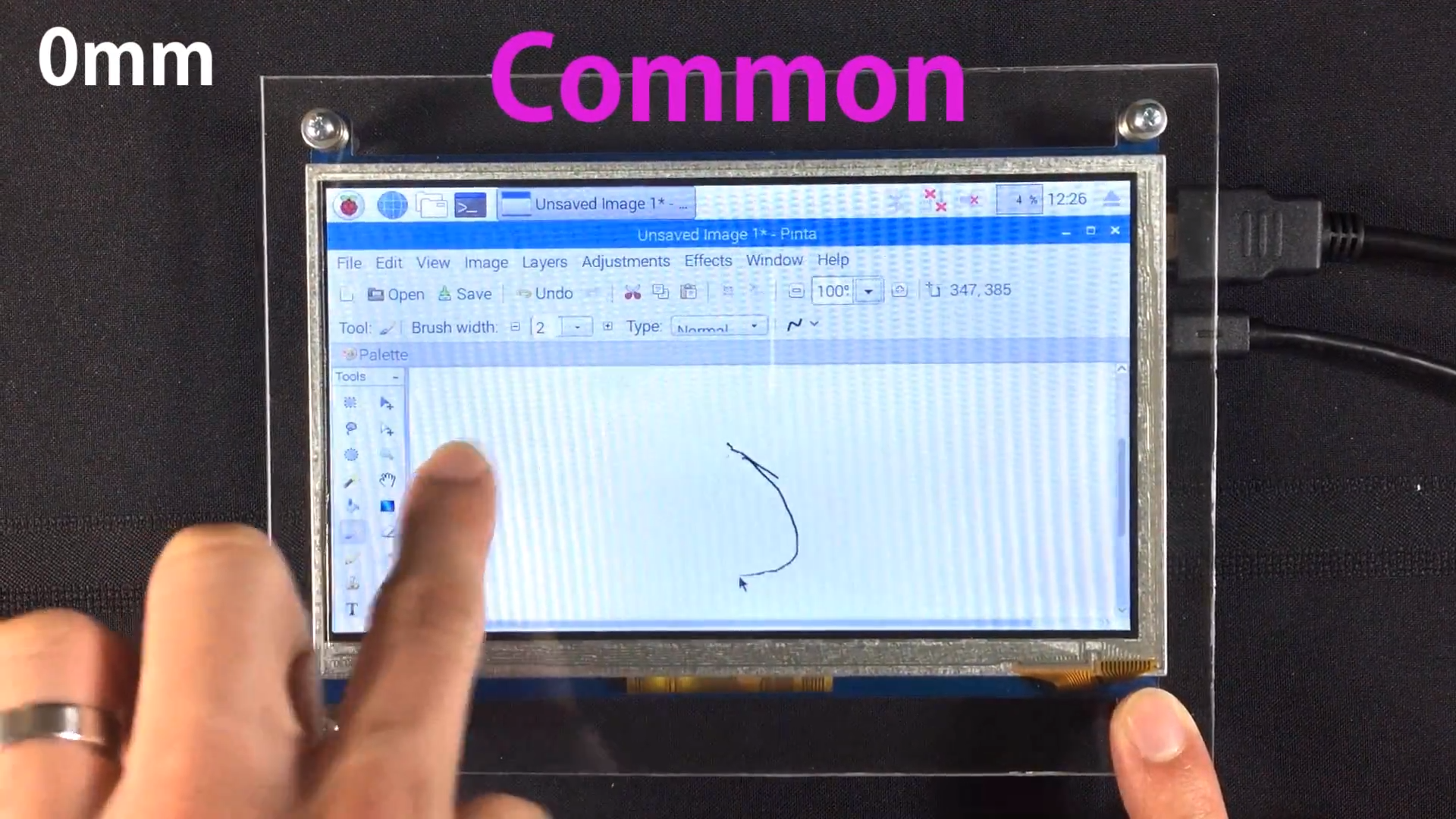

With no air gap, the MPCT touch panel works fine.

With no air gap, the common touch panel is very unreliable.

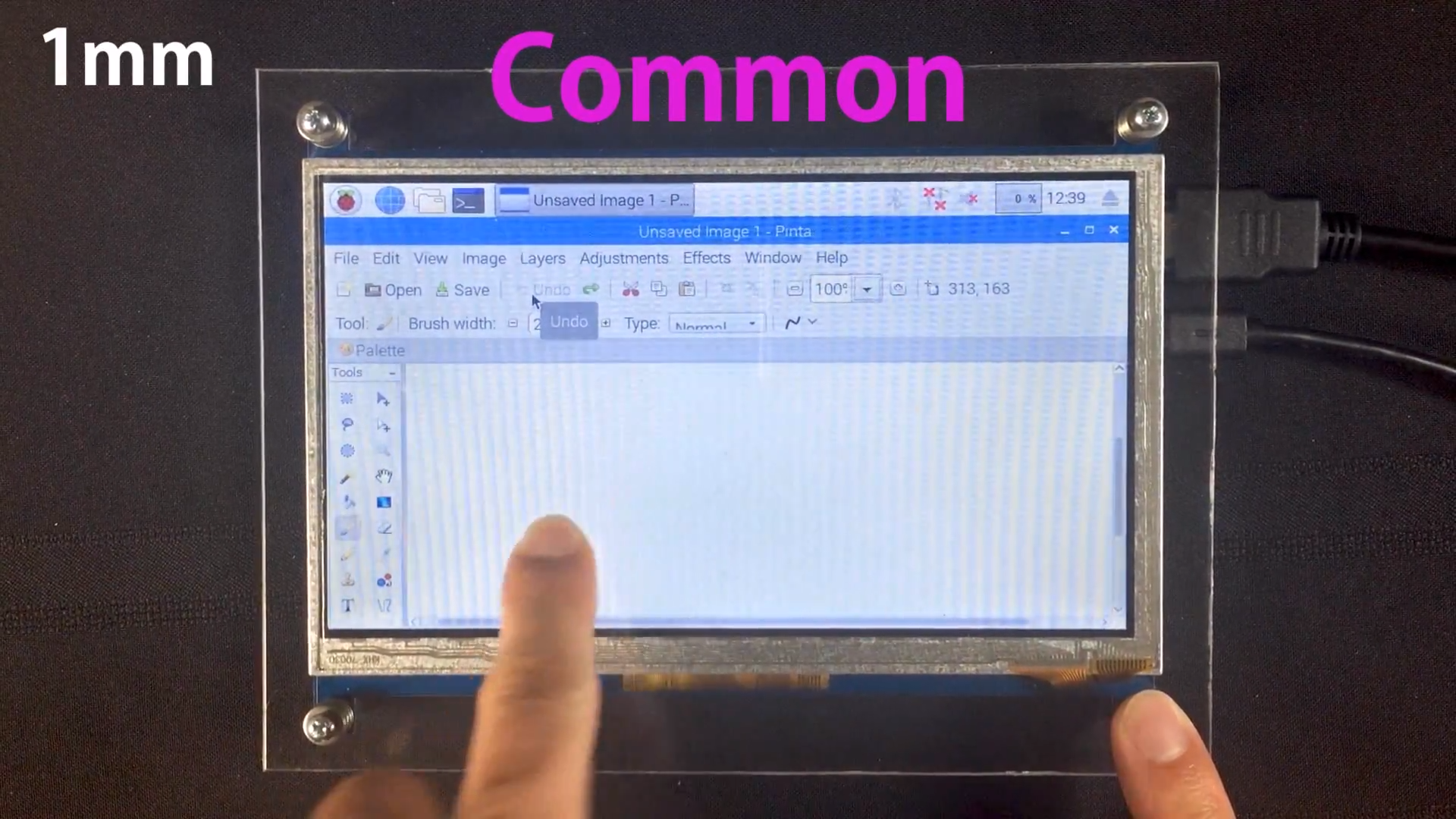

Touch test with a 1-millimeter air gap

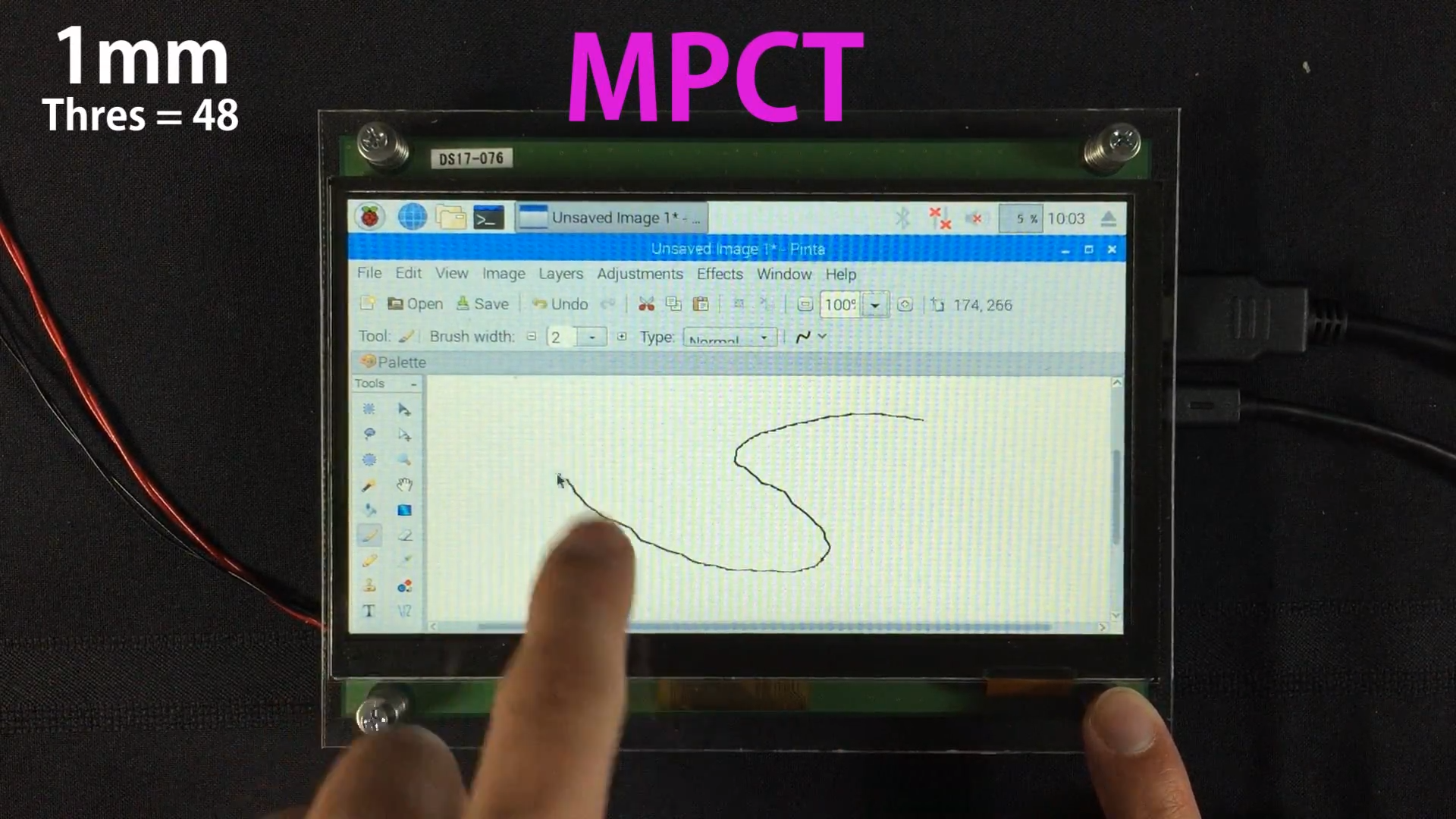

With a 1-millimeter air gap, the MPCT touch panel works fine.

The common touch panel, however, does not register any touch input whatsoever.

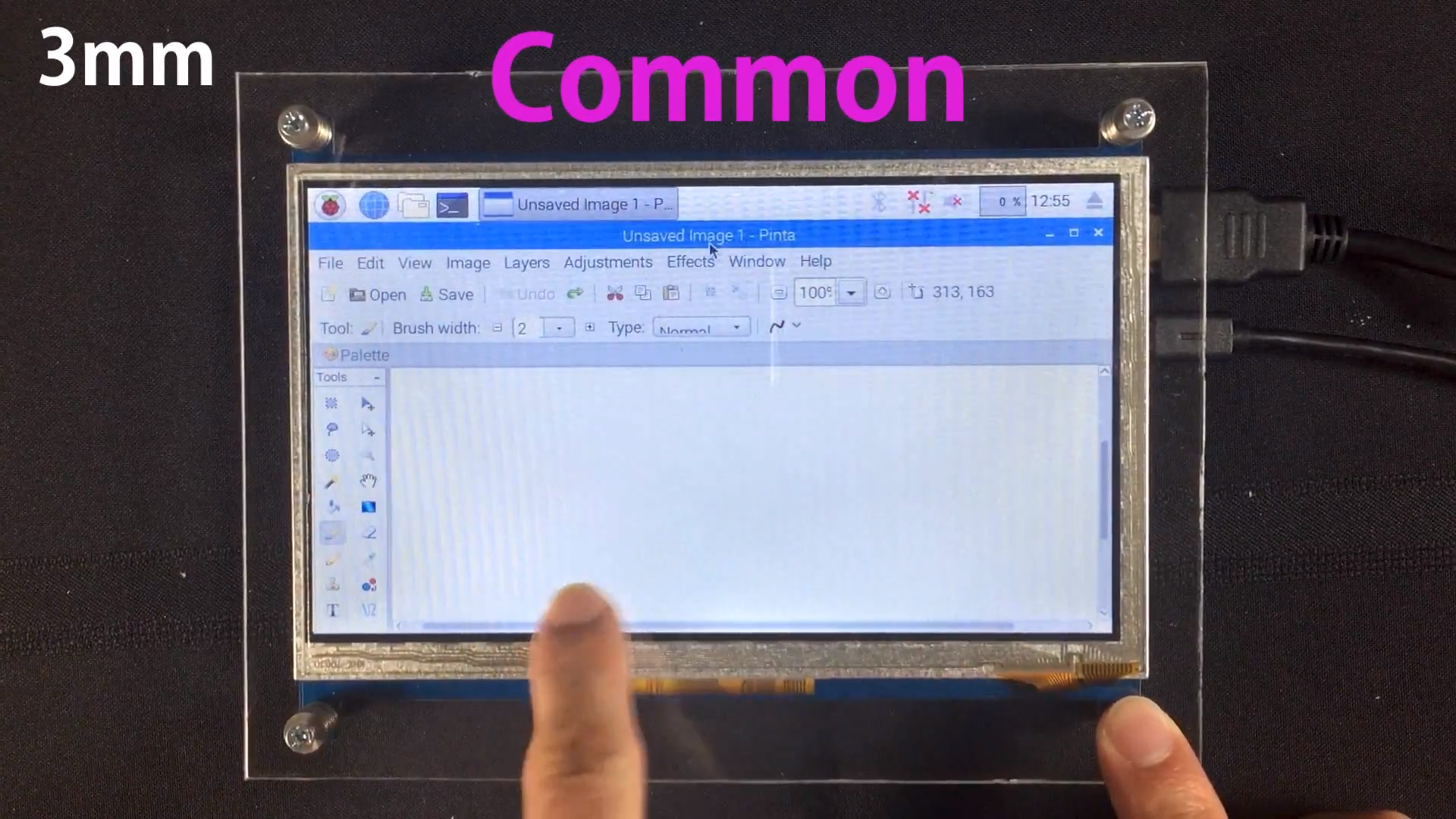

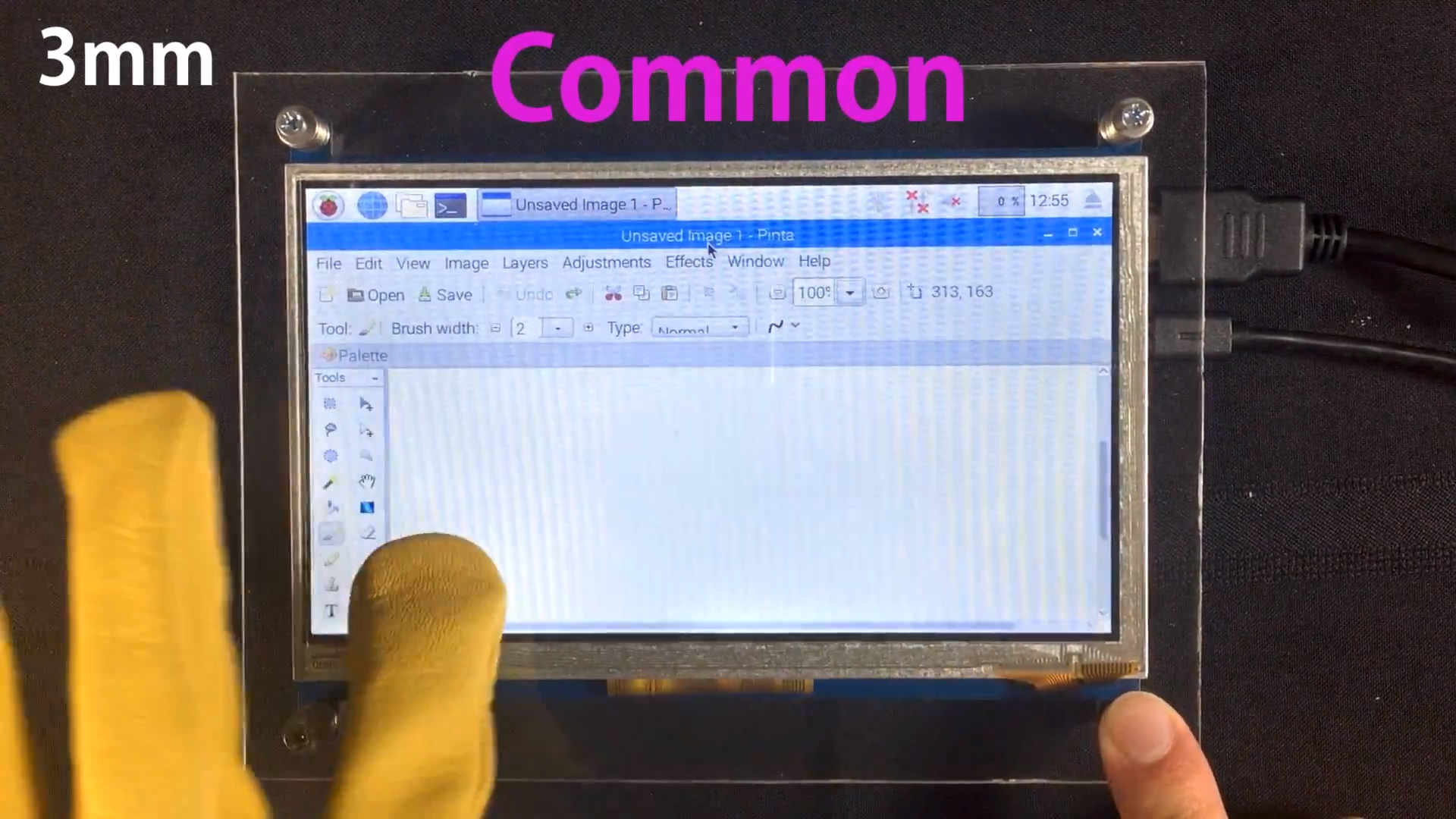

Touch test with a 3-millimeter air gap

With a 3-millimeter air gap, the MPCT touch panel works fine with a touch adjustment.

With a 3-millimeter air gap, the common touch panel does not register any touch input.

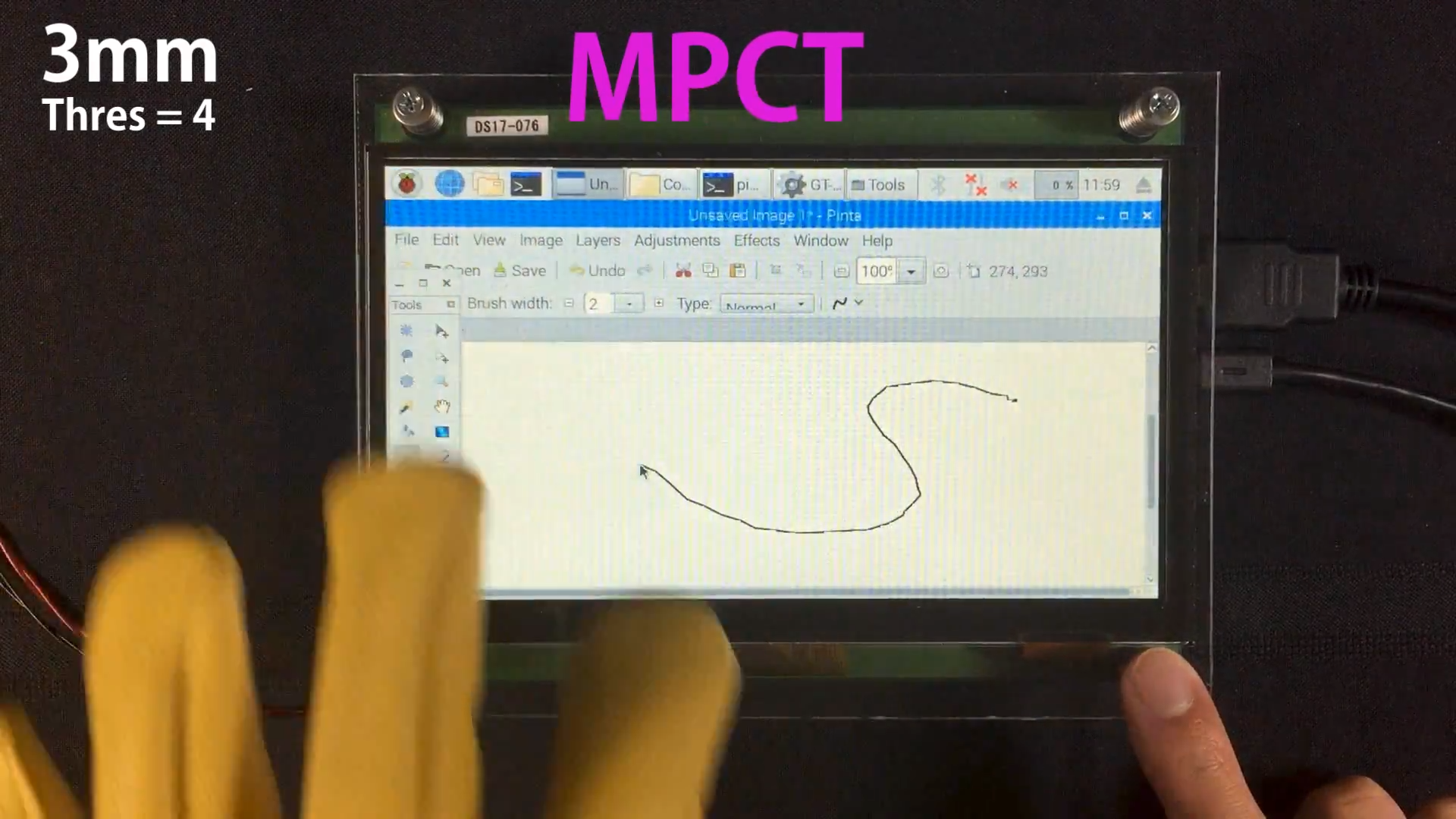

Touch test with a 3-millimeter air gap and leather gloves

MT

Using a leather glove, we can further compare the performance difference between the MPCT and the competitor’s touch panel.

Since the electrical field picks up the incoming touch input, it can effectively look through the glove and still complete the circuit through the finger.

Even when using leather gloves, the MPCT touch panel works fine.

However, the common touch panel doesn’t detect any touch input when using gloves.

Test Results

The difference between the MPCT and common touch panel is abundantly clear.

The MPCT touch panel has much more flexibility when it comes to environmental variables compared to the common touch panel.