Series: GT-VP Touch Comparison

GT-1P Touch Comparison | Overlay Thickness

Table of Contents

Last update: August 3, 2018

https://www.youtube.com/watch?v=ftaHT0ssu3w

This webpage is intended as a text supplement for the video above. This page will provide all of the necessary information (web links, images, etc.) that the video does if you are unable to view the video..

Overview and Connectivity

Overview

Unlike our competitors, the Noritake GT-1P module (GT800X480A-1303P) has a metallized projective capacitive touch (MPCT) panel that produces an extremely high signal-to-noise ratio, allowing it to perform exceptionally well in a variety of different environments with gloves, glass, acrylic cover plates, or when wet.

Below, we will compare the touchscreen capabilities of the Noritake GT-1P module and a competitor module.

Connectivity

Both the Noritake GT-1P module and competitor module accept digital video interface (DVI) through an HDMI (High-Definition Multimedia Interface) cable and touch via USB.

Below, we will examine the touchscreen performance of the Noritake GT-1P module and a competitor module under differing conditions. First, we will test them with no covering element. After that, we will test the modules using a glass plate overlay, then under a 2-millimeter thick acrylic plate overlay and finally under a 5-millimeter thick acrylic plate overlay.

Please Note

The touch sensitivity (threshold) level for the Noritake GT-1P module can be adjusted between a range of 0 and 255 while the competitor module cannot be adjusted at all. For these tests, the Noritake GT-1P module was set with a touch threshold of 48.

Touchscreen Comparison | Noritake GT-1P Module vs. Competitor Module.

For this test, we drew a single “S” on each module’s touch screen and observed how they performed. To start, we conducted a default test without any cover overlay.

Default Test (no cover)

The first test was performed without any cover overlay and the test consisted of drawing a single “S” on each of the module’s touchscreen.

Please Note

When using the competitor module, we need to have a finger on one of the mounting screws to ground the device so it works correctly.

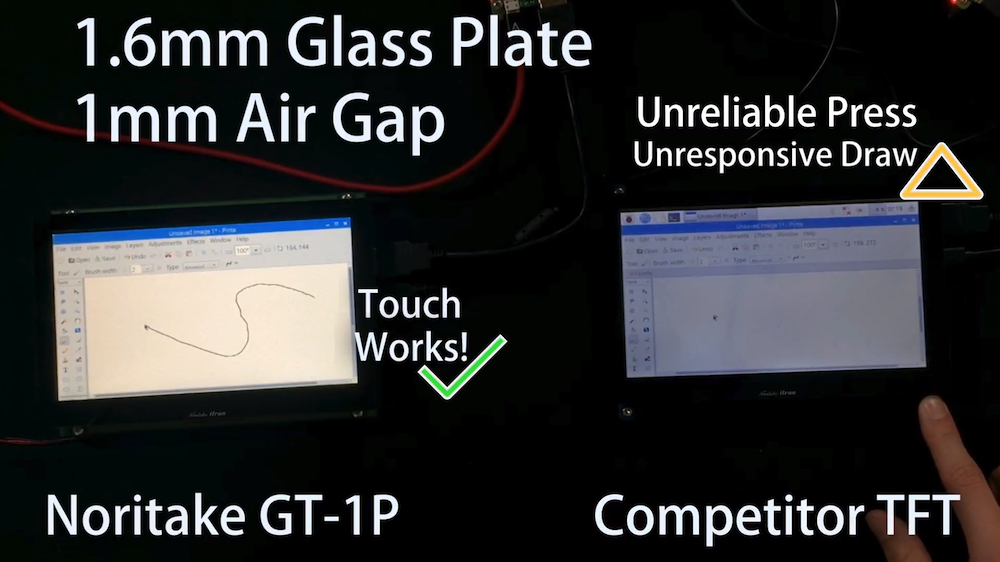

Glass Plate Test

Next, we overlaid a 1.6-millimeter thick glass plate onto each module’s touchscreen. Thin rubber mounting tape was attached to the glass to prevent slipping. This mounting tape created an approximate 1-millimeter gap between the touch screen and the glass.

We could clearly draw an “S” on the Noritake GT-1P module’s touchscreen. On the competitor model, however, press was unreliable and drawing was unresponsive.

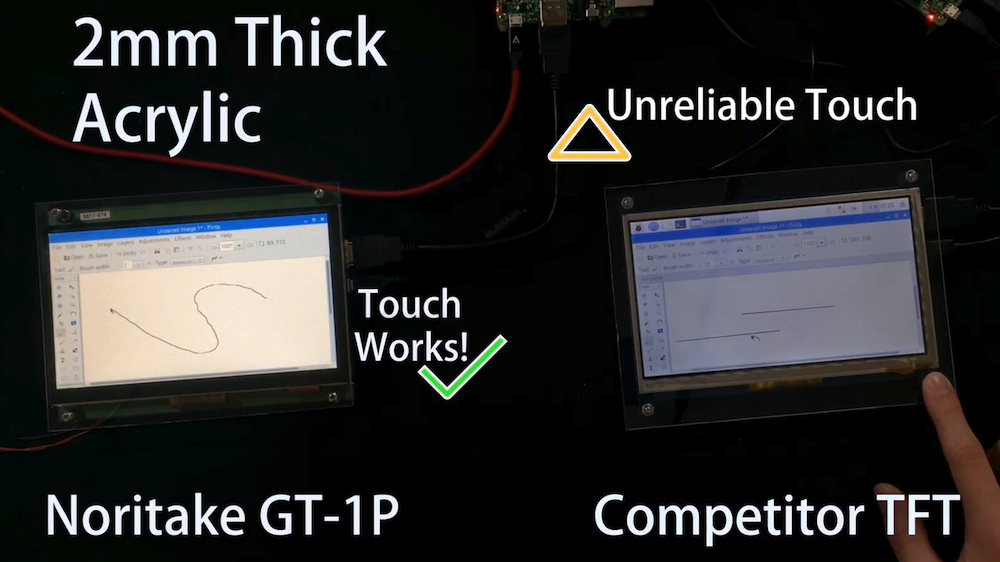

Two-millimeter Acrylic Plate Test

Next, we overlaid a 2-millimeter thick acrylic plate onto each module’s touchscreen.

We could clearly draw an “S” on the Noritake GT-1P module’s touchscreen. On the competitor model, however, press and drawing were unreliable.

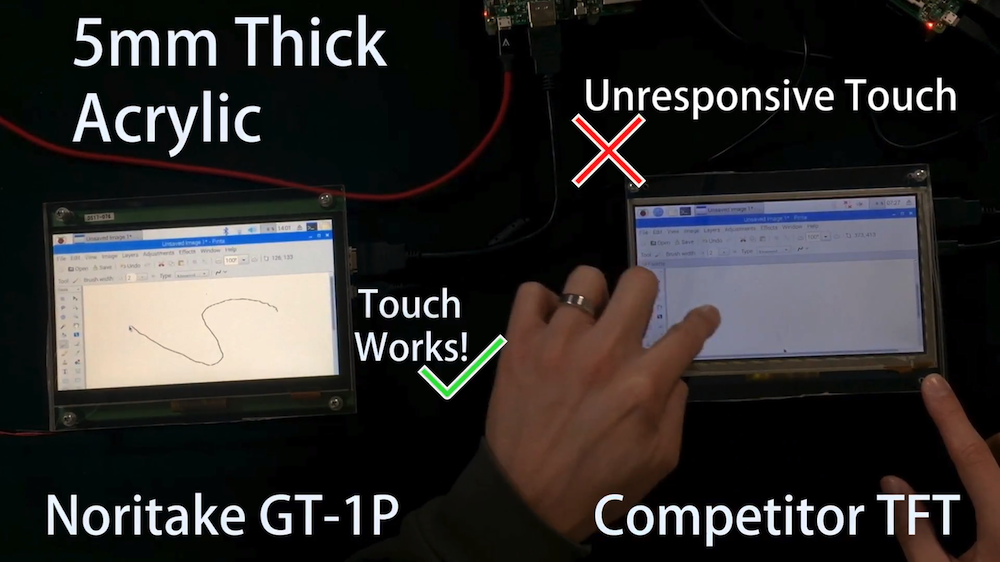

Five-millimeter Acrylic Plate Test

Next, we overlaid a 5-millimeter thick acrylic plate onto each module’s touchscreen.

We could clearly draw an “S” on the Noritake GT-1P module’s touchscreen. On the competitor model, however, press and drawing were unresponsive.

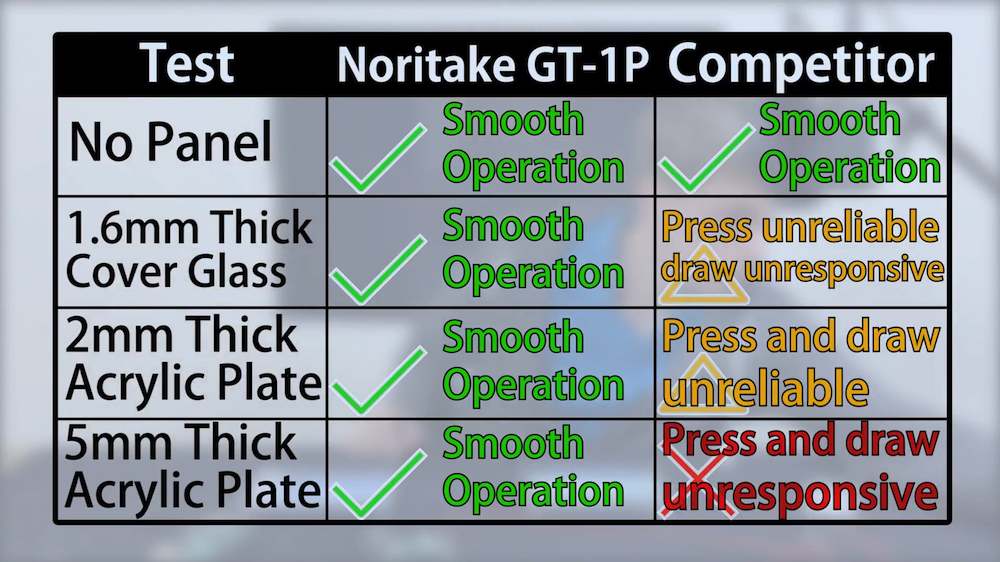

Test Results

The Noritake GT-1P module with its MPCT touchscreen clearly outperformed the competitor’s ITO touchscreen in a variety of conditions.

Here are the results: